The Best Vacuum Glazing Options: Why EN 674 Is the Correct Standard (and EN 673 Isn’t)

Understanding which standards genuinely reflect how vacuum units perform is vital for choosing the right high performance glazing. Vacuum insulated […]

Understanding which standards genuinely reflect how vacuum units perform is vital for choosing the right high performance glazing.

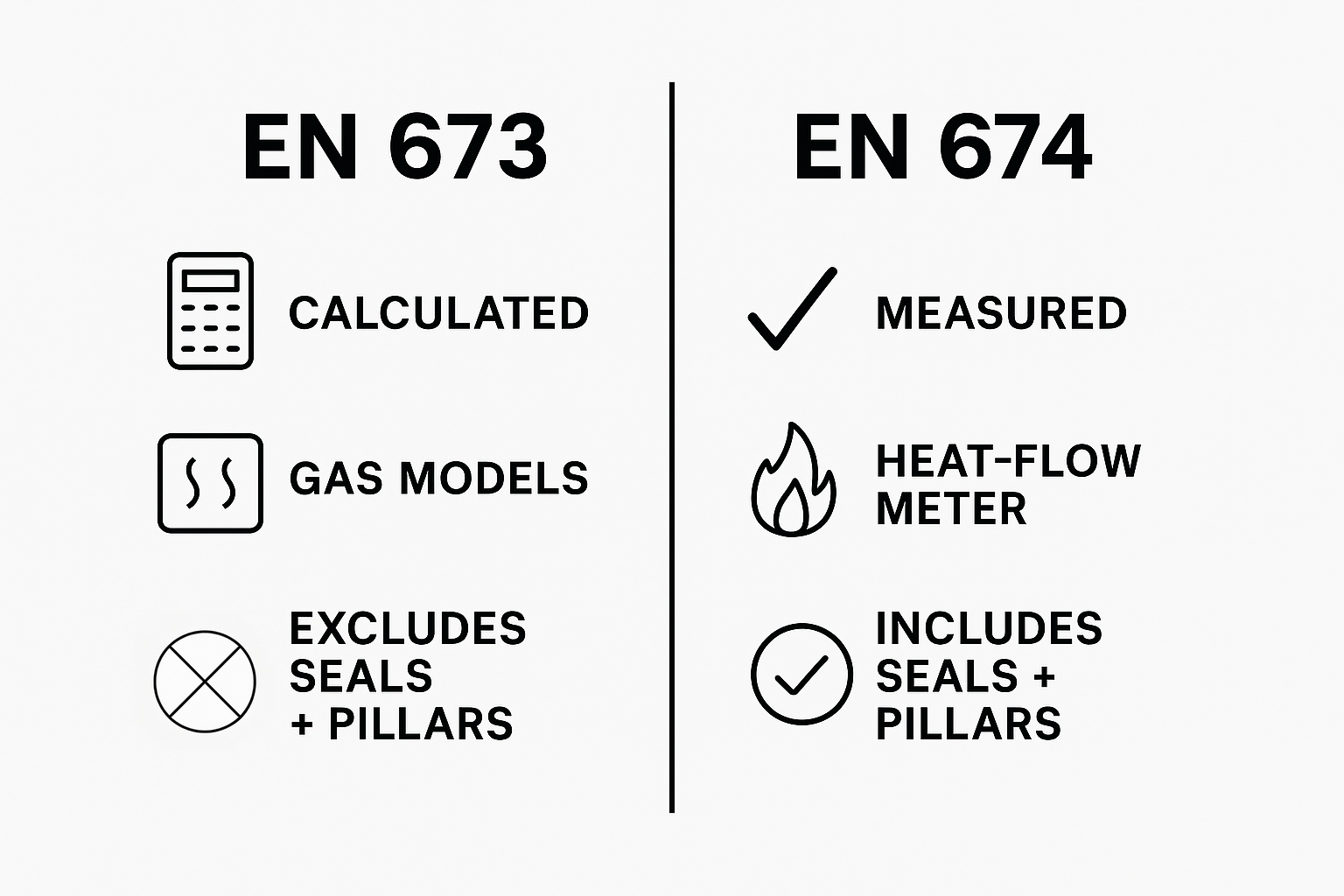

Vacuum insulated glazing (VIG) is a remarkable technology, delivering exceptional thermal efficiency in a slim profile ideal for heritage buildings and modern retrofits. However, when it comes to testing and verifying performance, not all standards are created equal. One of the most common misunderstandings in the market is the use of EN 673 to present U-values for vacuum glazing. While EN 673 is a well-established standard for standard insulating glass units, it is not suitable for vacuum glazing and can give an unrealistic picture of performance.

Why are EN 673 U-values unreliable for vacuum glazing?

EN 673 supports gas-filled double and triple glazing. It calculates U-values based on assumptions that include:

- heat transfer through gas

- consistent cavity conditions

- standard edge constructions

Vacuum glazing breaks every one of these assumptions.

More importantly, EN 673 excludes the two largest sources of heat transfer in vacuum units:

- The edge seal

Vacuum glazing uses a rigid perimeter seal, not a gas-filled IGU spacer. As a result, it behaves differently and contributes significantly to thermal bridging. EN 673 cannot model this behaviour, so it cannot include its effect.

- The internal micropillars

VIG units rely on microscopic support pillars to stop the panes collapsing under atmospheric pressure. These pillars conduct heat directly between panes. Therefore, they have a major impact on performance. However, EN 673 does not account for them in its calculations.

Because EN 673 ignores the defining heat-loss pathways in vacuum glazing, it cannot produce reliable results. So, when someone presents a VIG U-value calculated with EN 673, the figure may look optimistic. Yet it may also mislead, oversimplify, or fail to reflect real-world performance.

Why is EN 674 the correct standard for VIG U-value testing?

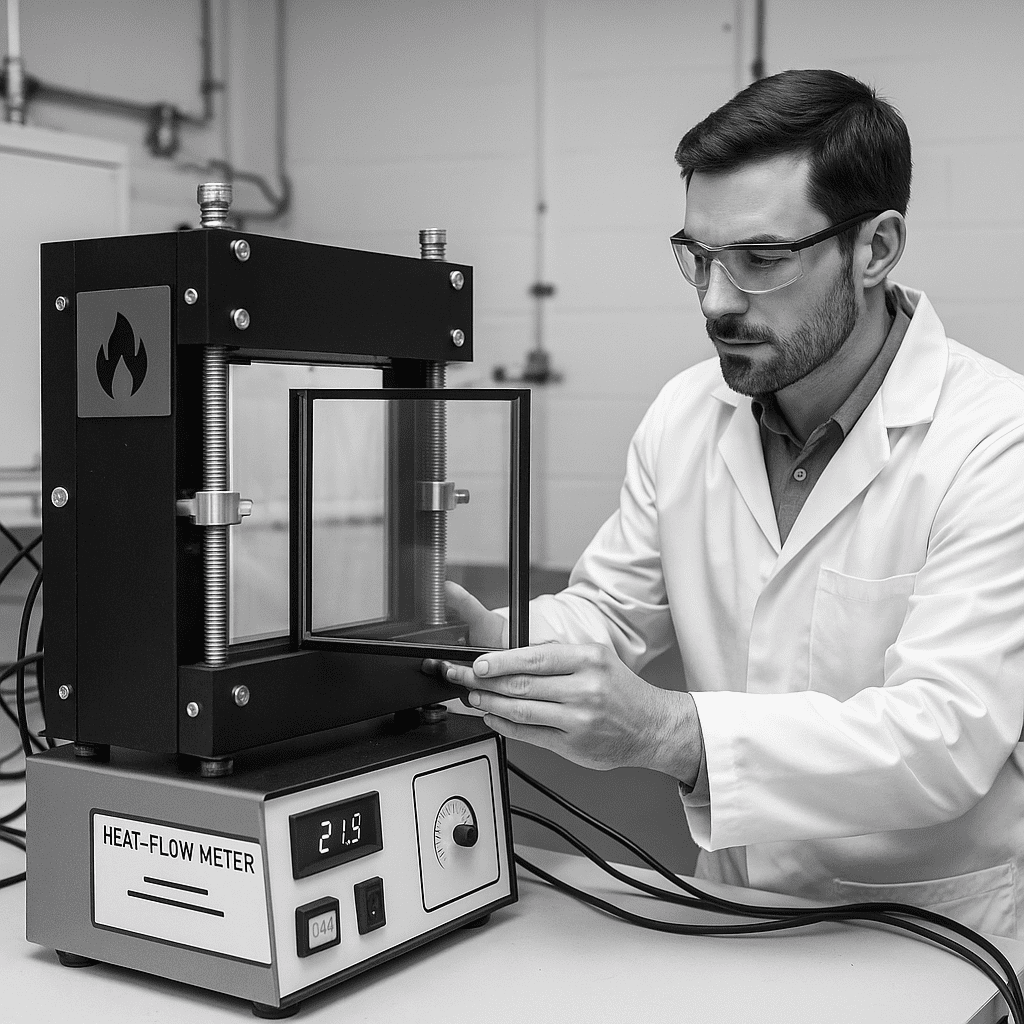

EN 674 measures heat transfer using a physical heat-flow meter. This matters because it tests actual performance, not simulated conditions. Crucially, VIG demands real measurement, not theoretical modelling.

EN 674 works because:

- It measures heat transfer through the glass, vacuum cavity, micropillars, and edge seal

- It removes reliance on gas-based assumptions

- It captures real thermal bridging effects unique to VIG

- It delivers comparable, consistent and product-representative results

For these reasons, most leading laboratories and VIG researchers rely on EN 674 when they test vacuum glazing performance.

How can you verify a vacuum glazing U-value claim is accurate?

When you compare vacuum glazing options, ask these core questions:

- Was the U-value measured using EN 674?

- Does the data include micropillar and edge seal performance?

- Did the test measure a real sample, not a model?

Then, take one final step. Confirm that the tested sample matches the product supplied. Often, manufacturers change pillar spacing, edge seals, or layouts, yet they fail to update test evidence. So, always check the test report reflects the exact unit you will receive.

These steps help you avoid unrealistic claims and identify genuinely high-performing products.

What are the risks of using the wrong U-value standard for VIG?

People frequently specify vacuum glazing for:

- listed buildings and conservation areas

- traditional slim-profile windows

- high-performance timber joinery

- specialist retrofit projects

- EnerPhit and Passiv-Haus type upgrades

In these contexts, accuracy is critical. Wrong assumptions lead to wrong calculations. In turn, this can affect predicted heat loss, design decisions, planning consent, long-term performance, and even warranties. When projects depend on precision, the margin for error disappears quickly.

Which standard should you trust for vacuum glazing performance?

To compare vacuum glazing products with confidence, trust EN 674. It measures real performance, reflects real physics, and accounts for the features that define VIG technology. Ultimately, it gives specifiers, manufacturers, consultants, and building owners the clarity they need to compare products fairly and make sound decisions.

Want help verifying real VIG performance for your project? Let’s talk standards, data, and tested results: