Vacuum Glazing vs Double Glazing: A Comprehensive Comparison

Discover the advantages of vacuum glazing over double glazing, including superior thermal performance, lighter construction, versatile installation options, and anti-condensation properties. Overcome misconceptions about price and impact resistance with innovative solutions like LandVac Optimum. Upgrade your buildings with vacuum glazing for energy efficiency and cost savings.

Vacuum Glazing vs. Double Glazing: Exploring the Superiority of Vacuum Insulating Glass

In today’s windows and doors market, insulating glass, especially double glazing, has become the go-to choice for its thermal performance and energy efficiency. However, recent advancements in technology have introduced a new contender: vacuum insulating glass. Vacuum glazing has shown remarkable performance that surpasses that of traditional double glazing, offering a range of benefits and advantages. In this post, we delve into a comprehensive comparison between vacuum glazing and double glazing. Our goal is to explore the strengths and weaknesses of both options, shedding light on why vacuum glazing is gaining recognition as a superior alternative. Whether you’re a homeowner, architect, or builder, understanding the advantages and disadvantages of these glass solutions will empower you to make an informed decision when it comes to selecting the most suitable option for your project. Join us as we uncover the exceptional qualities of vacuum glazing and its potential to revolutionise the windows and doors industry.

Vacuum Glazing vs Double Glazing

I. Advantages of Vacuum Glazing

A. Superior Thermal Performance

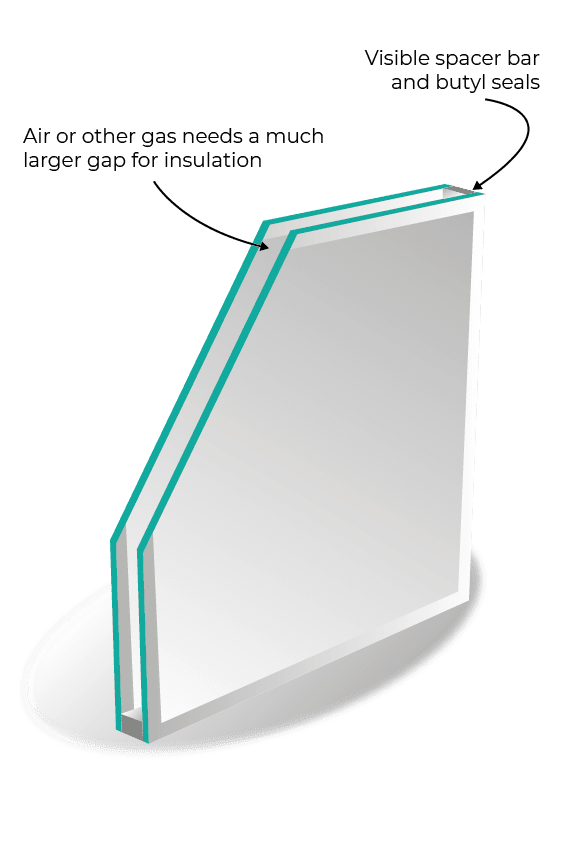

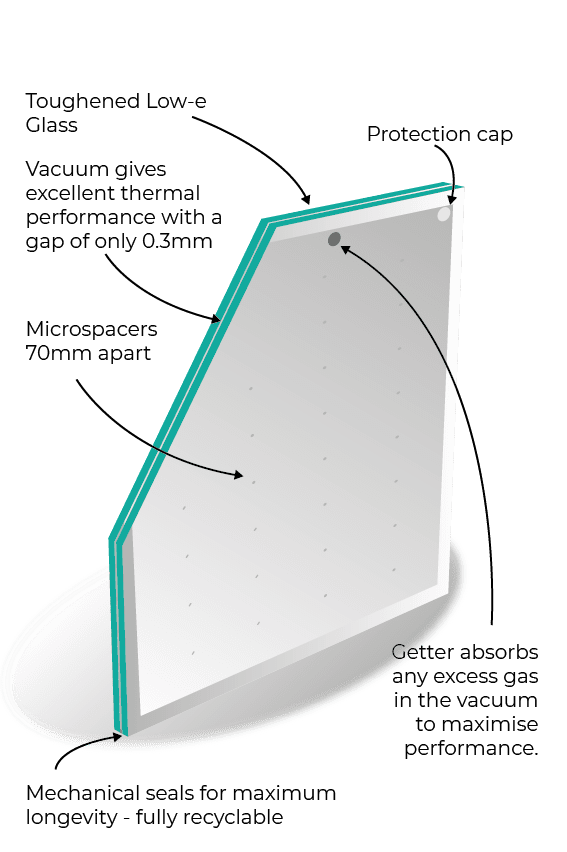

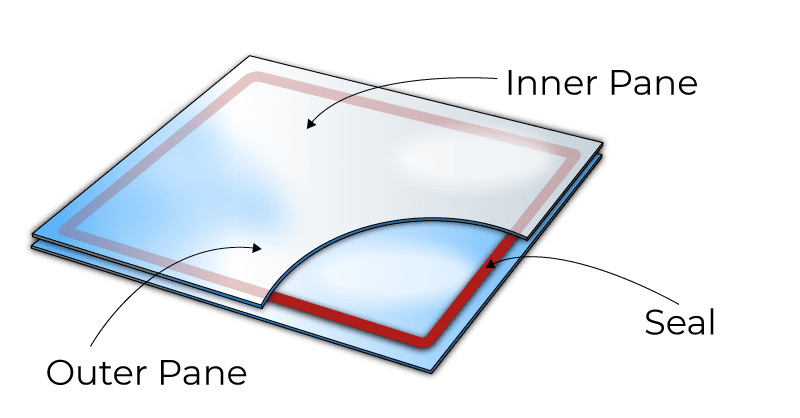

When it comes to heat transfer, double glazing has its limitations. The presence of air convection within insulating glass makes it challenging to achieve optimal thermal insulation. However, vacuum glazing presents a groundbreaking solution by eliminating air convection entirely. This innovative technology allows for superior thermal performance, ensuring remarkable energy efficiency and reduced heat loss.

To illustrate the thermal superiority of vacuum glazing, let’s compare it to double glazing. A comprehensive table showcasing the thermal performance metrics will demonstrate the significant difference in U-values and solar heat gain coefficients (SHGC) between the two. By examining these values, we can fully appreciate the remarkable insulation capabilities of vacuum glazing.

| Vacuum Glazing | Double Glazing | |

|---|---|---|

| Heat Transfer | Eliminates air convection | Air convection present |

| Thermal Insulation | Better insulation performance | Limited insulation performance |

| U Value | Lower U value (e.g., 0.4W/M2.K) | Higher U value (e.g., +1.0W/M2.K) |

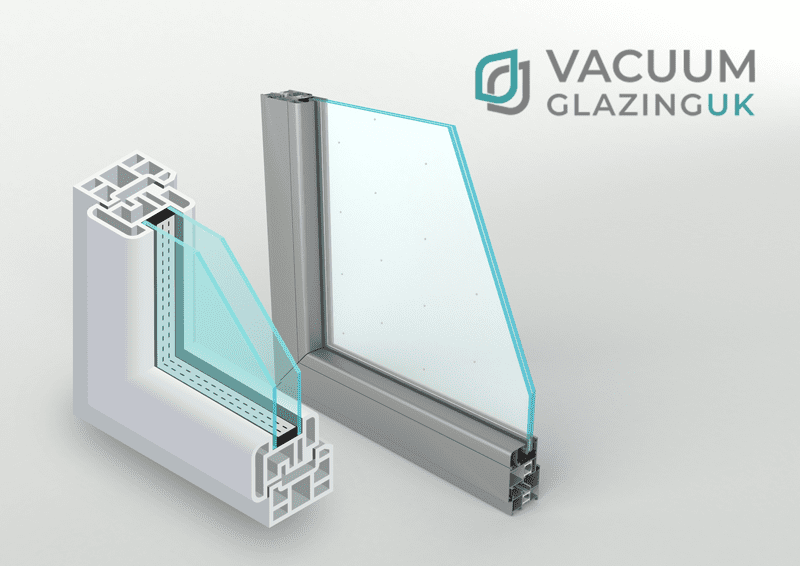

B. Thin Profile and Compatibility with Listed Buildings

One of the notable advantages of vacuum glazing is its remarkably thin profile. This feature is particularly beneficial when it comes to renovating older or listed buildings where the planning authority may require the preservation of the original single-glazed appearance. Vacuum glazing provides an ideal solution in such cases as it can maintain the slim sightlines of single glazing while delivering superior thermal insulation. By replacing the existing single glazing with vacuum glazing, the building can achieve enhanced energy efficiency without compromising its historical aesthetics.

Read more about Heritage Vacuum Glazing.

| Vacuum Glazing | Double Glazing | |

|---|---|---|

| Profile Thickness | Very thin profile (8.8mm) | Relatively thicker profile (+26mm) |

| Listed Buildings | Suitable for preservation and compliance | May not meet preservation requirements |

| Aesthetics | Preserves original single-glazed appearance | Alters the original single-glazed look |

C. Horizontal Installation Potential for Roof Lights

The installation position of insulating glass can impact its thermal performance. When installed horizontally, the U-value of traditional insulating glass increases due to gas convection. In contrast, vacuum glazing maintains consistent thermal insulation regardless of the mounting position. This means that whether it is used in glass roofs or skylights, the performance of vacuum glazing remains uncompromised, providing excellent energy efficiency and insulation.

| Vacuum Glazing | Double Glazing | |

|---|---|---|

| Thermal Performance | Consistent U-value regardless of mounting position | U-value may vary based on installation |

| Applications | Suitable for glass roofs and skylights | May have limitations in certain installations |

D. Applicability in Different Altitude Areas

Altitude variations pose challenges for insulating glass. When insulating glass manufactured at low altitudes is transported to higher altitudes, expansion becomes an issue. However, vacuum glazing eliminates this concern as it contains no air between the glass panes. When installed at higher places, vacuum glazing experiences less pressure difference and stress, ensuring both performance and safety. Additionally, the flatness of vacuum glazing makes it particularly suitable for use in facades, where visual distortion is undesirable.

| Vacuum Glazing | Double Glazing | |

|---|---|---|

| Altitude Challenges | Reduced pressure difference and stress | Potential expansion issues |

| Altitude Benefits | Suitable for plateau areas and specific altitude requirements | Limitations at higher altitudes |

E. Superior Anti-Condensation Performance

Condensation can be a persistent problem with traditional insulating glass, leading to foggy glass surfaces and reduced visibility. In contrast, vacuum glazing effectively addresses this issue. With its sealed edges, vacuum glazing eliminates the possibility of condensation. By maintaining the interior glass surface temperature above the dew point, it ensures clear visibility and prevents any negative effects of condensation. This makes vacuum glazing especially suitable for applications in areas with extreme cold weather conditions.

| Vacuum Glazing | Double Glazing | |

|---|---|---|

| Condensation Risks | Sealed edges eliminate condensation | Potential for condensation on interior glass surface |

| Dew Point Comparison | Lower dew point (e.g., -36°C) | Higher dew point (e.g., -8°C) |

F. Enhanced Soundproof Performance

Urban environments are often plagued by various sources of noise, including traffic, construction, and general living sounds. Vacuum glazing offers superior soundproofing capabilities, particularly against low and middle-frequency noise. By comparing the weighted noise reduction index of vacuum glazing to that of double glazing, the significant difference becomes evident. This makes vacuum glazing an excellent choice for buildings located in noisy areas, providing occupants with a quieter and more peaceful environment.

| Vacuum Glazing | Double Glazing | |

|---|---|---|

| Sound Reduction Index | Higher sound reduction index (e.g., 39 – 41dB) | Lower sound reduction index (e.g., 31dB) |

| Noise Applications | Suitable for buildings in noisy areas | May not provide optimal noise reduction |

G. Longer Lifespan

The lifespan of vacuum glazing surpasses that of traditional insulating glass. While insulating glass typically offers an average service life of around 15 years, vacuum glazing can endure for more than 25 years. This longevity is attributed to the use of durable sealing materials, such as solder glass, which ensures the integrity and longevity of the vacuum space. With its extended lifespan, vacuum glazing proves to be a reliable and long-lasting investment in energy-efficient windows and doors.

| Vacuum Glazing | Double Glazing | |

|---|---|---|

| Lifespan | Extended service life (over 25 years) | Average lifespan (around 15 years) |

| Sealing Materials | Durable sealing materials used | Aging materials can affect longevity |

In the next section, we will explore some of the challenges and limitations associated with vacuum glazing. By examining these aspects, we can gain a comprehensive understanding of its suitability for different applications.

Section II: Addressing Criticisms and Debunking Myths in Vacuum Glazing

A. High Price

One common criticism of vacuum glazing is its initial higher cost compared to double glazing. However, it is important to consider the long-term benefits and return on investment (ROI) that vacuum glazing offers. While the upfront installation cost may be higher, the energy savings achieved through superior thermal performance can quickly offset this initial investment.

With the rising costs of energy and increasing concerns about environmental sustainability, there has never been a better time to prioritise energy efficiency in homes and buildings. Vacuum glazing significantly reduces heat transfer and provides better insulation than double glazing. As a result, homeowners can experience substantial savings on their heating bills.

By minimising heat loss during the colder months and reducing heat gain during the warmer months, vacuum glazing helps maintain a more stable indoor temperature. This reduced reliance on heating and cooling systems directly translates into lower energy consumption and cost savings in the long run.

It is essential to view the higher price of vacuum glazing as an investment in energy efficiency and comfort. In the current landscape of high energy prices, taking steps to increase the thermal efficiency of homes has become a priority for many homeowners. With vacuum glazing, these individuals can make their homes more affordable to run while also reducing their carbon footprint.

In summary, while the initial cost of vacuum glazing may be higher, the significant energy savings and improved comfort it provides make it a worthwhile investment, particularly in the context of rising energy prices. By prioritising energy efficiency and reducing heat loss, vacuum glazing can help homeowners achieve a more sustainable and cost-effective living environment.

Section II: Addressing Criticisms and Debunking Myths

B. Low Impact Resistance

One criticism that has been associated with vacuum glazing is its perceived low impact resistance. However, it is important to note that not all vacuum glazing products are created equal, and advancements in technology have led to improved impact resistance in certain vacuum glazing systems.

While some manufacturers may have faced challenges in ensuring adequate impact resistance, it is crucial to highlight that Landvac, a leading provider of vacuum glazing, incorporates toughened glass as a standard feature in their installations. Toughened glass, also known as tempered glass, undergoes a process of thermal or chemical treatment that enhances its strength and resistance to impact.

By utilising toughened glass in their vacuum glazing products, Landvac addresses the concern of low impact resistance. This means that their installations can withstand moderate impacts without shattering or compromising the structural integrity of the glazing.

It is important for homeowners and builders to be aware of the quality and specifications of the vacuum glazing they choose. By selecting reputable manufacturers like Landvac, who prioritise the use of toughened glass, the issue of low impact resistance can be effectively addressed.

In summary, while low impact resistance has been associated with some vacuum glazing products, Landvac stands out by incorporating toughened glass as a standard feature in their installations. By choosing vacuum glazing systems from trusted manufacturers, such as Landvac, homeowners can ensure that their installations provide the desired level of impact resistance, offering both durability and peace of mind.

C. Poor Edge Thermal Conductivity

One criticism often associated with vacuum glazing is its perceived poor edge thermal conductivity. It is true that the edge seal in vacuum glazing is not as thermally efficient as the central pane. However, it is essential to understand the overall impact of this factor on the performance of the window as a whole.

While the edge seal may have slightly higher thermal conductivity compared to the centre pane, it is important to note that the negative effects of the edge seal are far offset by the superior thermal performance of the entire window unit. In larger window units, the impact of the edge seal’s thermal conductivity on the overall performance is minimal.

However, it is worth mentioning that for those seeking even greater edge thermal performance, there are options available in the market. One such option is LandVac Optimum, a hybrid triple glazed window that combines the benefits of vacuum glazing with a traditional spacer bar.

LandVac Optimum features a specially designed spacer bar that enhances the edge thermal conductivity, making it just as efficient as in double glazing. This innovative solution addresses any concerns regarding edge thermal conductivity, ensuring that the window performs at its optimum level.

By incorporating a traditional spacer bar, LandVac Optimum provides an additional layer of insulation at the edge, minimising any thermal bridging and maximising the overall energy efficiency of the window. This hybrid approach offers the best of both worlds, combining the exceptional thermal performance of vacuum glazing with the enhanced edge performance of traditional double glazing.

In summary, while vacuum glazing may exhibit slightly higher thermal conductivity at the edge seal compared to the central pane, the performance of the window as a whole is not significantly compromised. Moreover, for those seeking an even higher level of edge thermal performance, solutions such as LandVac Optimum offer a hybrid triple glazed window with a traditional spacer bar, ensuring that the edge efficiency is on par with double glazing. The availability of such options further emphasizes the versatility and adaptability of vacuum glazing technology to meet specific requirements and address any concerns regarding edge thermal conductivity.

Read more about the thermal conductivity of the spacer in vacuum glazing in this post.

Conclusion

In conclusion, the comparison between vacuum glazing and double glazing highlights the numerous advantages and some misconceptions associated with vacuum glazing. As a superior alternative to traditional insulating glass, vacuum glazing offers a range of benefits that make it a compelling choice for modern buildings.

From superior thermal performance and energy efficiency to lighter and thinner construction, vacuum glazing proves to be a cost-effective and sustainable solution. Its ability to maintain consistent U-values regardless of installation position, applicability in different altitude areas, superior anti-condensation performance, enhanced soundproofing capabilities, and longer lifespan further contribute to its appeal.

While some criticisms have been raised, such as the initial higher cost of installation and concerns about impact resistance and edge thermal conductivity, advancements in vacuum glazing technology have addressed these issues. Manufacturers like LandVac have introduced innovations such as toughened glass and hybrid triple glazed windows with traditional spacer bars to overcome these challenges and provide efficient solutions.

As energy prices continue to rise, there has never been a better time to invest in increasing the thermal efficiency of buildings. Vacuum glazing offers an opportunity to significantly reduce heating costs, leading to a return on investment in the long run.

Overall, vacuum glazing stands as a remarkable alternative to double glazing, offering improved performance, energy efficiency, and durability. It is an ideal choice for both new constructions and renovation projects, providing enhanced comfort, sustainability, and cost savings.

As the demand for energy-efficient and environmentally friendly solutions grows, vacuum glazing is poised to play a crucial role in shaping the future of the windows and doors market. By understanding its advantages, debunking misconceptions, and exploring innovative options like LandVac Optimum, stakeholders can make informed decisions and embrace the benefits that vacuum glazing brings to the table.

Embrace the power of vacuum glazing and experience a new level of thermal performance, energy efficiency, and sustainability in your buildings. Together, we can create a greener and more comfortable future.