About Flexible Edge Sealing

We explain why Vacuum Glazing has flexible edge sealing to extend its service life.

What is the Flexible Edge Sealing in vacuum double glazing?

Vacuum glazing offers a highly efficient solution for reducing heat loss in buildings. With improved windows, you can effectively retain heat, which is particularly valuable in light of rising energy prices. If you’re considering upgrading to more efficient windows, this article provides valuable insights into the manufacturing process and why vacuum glazing might be the ideal choice for insulating your home.

Understanding Vacuum Double Glazing:

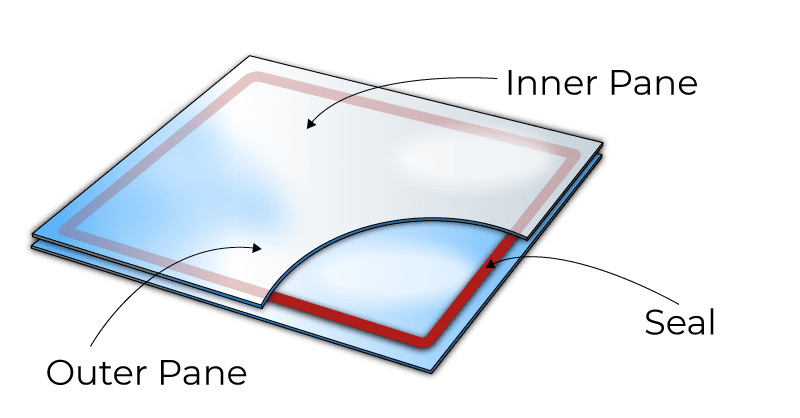

Vacuum glazing originated as a lightweight solution for earthquake-prone areas, ensuring both safety and energy efficiency. Over time, this technology has evolved to deliver superior energy efficiency, durability, and acoustic performance. Similar to standard double glazing, vacuum glazing consists of two glass panes. However, instead of a gas-filled cavity, it utilises a vacuum, offering two significant advantages: enhanced insulation capabilities and a visually appealing design. The narrow gap, as small as 0.3mm, effectively prevents heat transfer while maintaining a slim aesthetic profile.

You can find out more about how Vacuum Glazing works here on our What is vacuum Glazing page.

Challenges of Rigid Edge Seals in Vacuum Glazing

One of the primary challenges associated with vacuum glazing technology is the use of rigid edge seals. When vacuum glazing was initially developed, rigid edge seals were commonly used to create a hermetic seal between the glass panes. However, these rigid seals presented various issues, particularly in terms of their durability and performance under different environmental conditions.

One significant challenge arises from temperature differentials. All glazing units experience significant variations in temperature, with the outer pane being exposed to the external environment while the inner pane is subjected to controlled conditions within the building. These temperature differentials cause expansion and contraction of the glass, leading to considerable stresses in the edge seal region. Rigid edge seals are more prone to failure under such stress, resulting in compromised performance and potential air leakage.

Another challenge is the impact of atmospheric pressure. Vacuum glazing relies on the creation of a low-pressure environment between the glass panes to enhance insulation properties. However, atmospheric pressure exerts significant force on the edges of the glazing unit, especially during extreme weather conditions or buildings that are located at higher altitudes. Rigid edge seals may struggle to withstand this pressure, leading to seal failure and reduced efficiency of the vacuum glazing.

Moreover, the mechanical strength of rigid edge seals is crucial for the long-term integrity of vacuum glazing. The edges of the glass panes must be securely sealed to prevent the ingress of air and moisture, which could compromise the insulating properties of the vacuum. Rigid seals may not possess sufficient mechanical strength to withstand the stresses induced by temperature differentials, causing them to deform, crack, or detach over time.

To address these challenges and enhance the performance and durability of vacuum glazing, the concept of flexible edge sealing has been introduced. Flexible edge seals aim to mitigate the stress-related issues associated with rigid seals, including bending of the entire glazing unit and the potential for seal failure due to temperature differentials. By adopting flexible edge sealing techniques, vacuum glazing manufacturers can ensure a more robust and reliable edge seal that can withstand environmental stresses and maintain the vacuum integrity over the lifespan of the glazing unit.

Enhancing Durability and Performance with Flexible Edge Sealing

Flexible edge sealing in vacuum glazing emerged as a solution to address the limitations of early rigid edge seals. When vacuum glazing was initially developed, rigid edge seals were prone to failure under varying temperatures and atmospheric pressure conditions. In scientific research on the subject, it has been highlighted that the edge seal plays a crucial role in maintaining the integrity and durability of vacuum glazing.

The edge seal region experiences significant stresses caused by temperature differentials and atmospheric pressure. To ensure long-term performance, the edge seal must remain hermetic and possess mechanical strength to withstand these stresses. Recognising the challenges associated with rigid edge seals, the concept of flexible edge sealed vacuum glazing was introduced.

By incorporating a flexible edge seal, vacuum glazing aims to mitigate stress-related issues, such as overall glazing bending and the potential failure of the edge seal due to expansion and contraction. This innovative approach enhances the reliability and longevity of vacuum glazing systems, ensuring their optimal performance in various environmental conditions.

By adopting flexible edge sealing techniques, vacuum glazing manufacturers can overcome the challenges associated with temperature differentials and atmospheric pressure, providing a robust and durable solution for energy-efficient windows in residential and commercial buildings.

If you are interested in learning more about edge sealing in vacuum glazing, this article contains detailed information on the research and the science behind it: https://zenodo.org/record/1131914/files/10007776.pdf